Biodiversity choked with plastic

From the Arctic to the Antarctic, whether in rivers, near the coast or out at sea, it cannot be denied: our pollution is omnipresent. From the microplastics that we see in each of our surface plankton nets, or in sediments, to the more insidious chemical pollution, which can’t be seen. The scale of the phenomenon makes it an issue of the century.

The Ocean shows that the solutions to this pollution are on land, at the source of the problem, and reminds us every day of the importance of sustainable development, and in particular of a more frugal and circular economy.

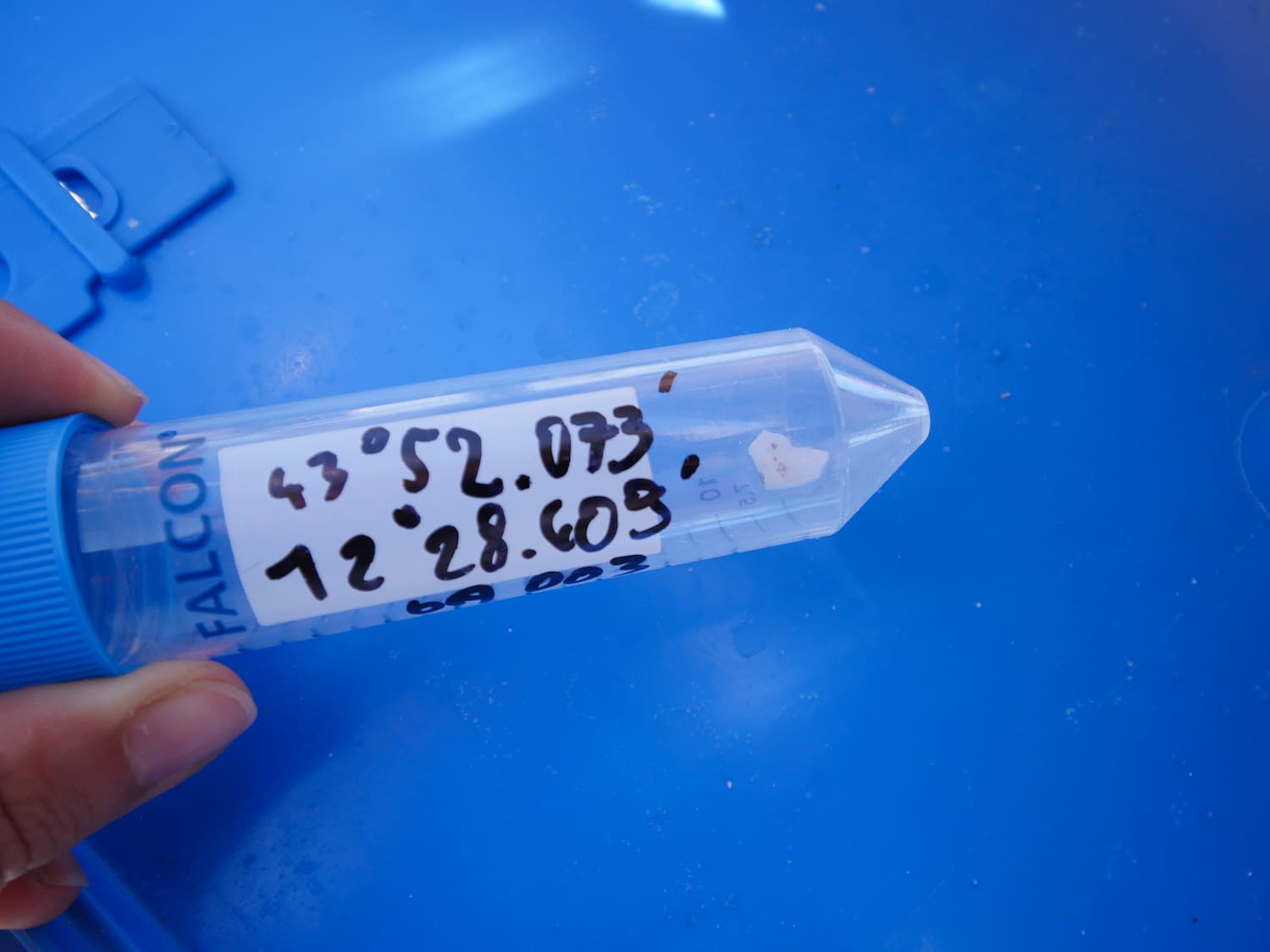

- 93 % of plastic waste in the sea is less than 5 mm in size

- 100 % of chemical pollution from the land ends up in the sea

- 1M tonnes of plastic discharged into the ocean every year

- 40 % of the plastics that wash up on the banks of our rivers are polystyrene

Our expeditions

Mission Microbiomes

Current expedition

Better understanding the invisible life of the ocean

Having identified and shared a large number of species of plankton, their genes and their forms with the international scientific community since 2009, this new expedition decided to take an overall approach and treat the oceanic ecosystem as a whole. To achieve that, we need to get back to the basics, to the first link in the ecosystem: the microbiome.

Tara Microplastiques

Analyses in progress

More…

Invisible pollution

Fondation Tara Océan news

Immerse yourself in our expeditions

Fighting to protect marine biodiversity from pollution

Discover our commitments and climate research

Learning more about biodiversity to help better protect it

Discover our commitments and research for the Arctic